ENNS BROS STREAMLINES WITH INTELLIDEALER

Editors Note: IntelliDealer is now the flagship solution of CDK Global Heavy Equipment and Frank DeDecker (at the time of the case study VP Development and owner of PFW Systems) is now Sr. Director Client Services at CDK Global Heavy Equipment. The LANSA-developed IntelliDealer solution is now used from over 1500 customer locations, the majority of customers choosing for the SaaS option, while the on-premise offering remains popular as well.

Enns Brothers, based in Manitoba, Canada,has been selling and servicing John Deere equipment for over 50 years and now also ATVs and Ski-Doo’s from BRP (Bombardier). Enns Bros used IntelliDealer and eServices, an integrated solution for heavy equipment dealerships from LANSA partner PFW Systems Corporation, to streamline its business and improve service by giving technicians, supervisors and customers access to real-time work order and detailed equipment information.

Enns Brothers, based in Manitoba, Canada,has been selling and servicing John Deere equipment for over 50 years and now also ATVs and Ski-Doo’s from BRP (Bombardier). Enns Bros used IntelliDealer and eServices, an integrated solution for heavy equipment dealerships from LANSA partner PFW Systems Corporation, to streamline its business and improve service by giving technicians, supervisors and customers access to real-time work order and detailed equipment information.

“IntelliDealer gives me total visibility and eliminates many wasted man-hours in the workshop.” says Bert Gregoire, aftermarket manager at Enns Bros. “The eServices portal answers the majority of customer queries and, as our parts and service business is 10 million dollars annually, it paid for itself very quickly and also increased sales.”

IntelliDealer gives me total visibility and eliminates many wasted man-hours in the workshop.

- Building a Better User Interface

- A Smooth Transition

- The Benefits of Real-time Data

- Total Visibility of Information

- Company and System Information

Building a Better User Interface

PFW’s Dealership Management System has been a market leader for over 20 years, but the company knew it had to develop a successor to its classic RPG green-screen product. While client server was all the rage during the nineties, this was not the direction PFW wanted to go as Frank DeDecker, VP development at PFW Systems Corporations, explains. “We have hundreds of clients across Canada and America. Some of our customers have over 1,500 users spread over 50 locations. Having to install and maintain client software would be a deployment nightmare.”

After using LANSA to extend the product and give web access to customers and mobile staff, PFW decided to redevelop its entire dealership system for browser access with Visual LANSA.

“LANSA gave us the iSeries capability we were keen on – but without locking us in. We saw a gradual migration with LANSA as an easier way for our customers and ourselves to move forward. Visual LANSA also gives us the ability to offer the new system, IntelliDealer, in an ASP or Windows browser environment,” says DeDecker.

A strong focus on parts and service is one of the key differentiating factors between heavy equipment and car dealerships, according to DeDecker. Enns Bros is a good example of this – with over 75 per cent of its 100+ staff working in product support and 85 per cent of its 170,000 square feet of shop, warehouse and office space dedicated to after sales service – generating over 10 million dollars annually.

Enns Bros started using PFW’s classic solution in the eighties. While the database structure and functionality of the classic solution was well designed, its user interface was not always intuitive, especially for new staff.

“Supervisors had to open multiple green-screen sessions and could not easily navigate to information about pending work orders, technician workloads and other resources,” explains Gregoire.

“But the critical fact was that information was always out of date.”

“Technicians had to punch their time card to clock the start and finish times for a work order, walk over the shop floor to give the supervisor the log sheet, wait a few minutes because the supervisor would be busy, get the sheet with details of the next work order, walk back to the service bay, punch the time card again, and so on. Then, someone had to enter the hand-written log sheets into the system.”

“When a customer called to find out when their tractor would be ready, no one could give an accurate answer unless we walked down to the shop floor to find out.”

As most of IntelliDealer’s modules were already available and since the database structure remained largely unchanged, Enns Bros decided it was time to gradually move over to the browser-based solution from the classic system.

LANSA gave us the iSeries capability we were keen on – but without locking us in. Visual LANSA also gives us the ability to offer IntelliDealer in an ASP or Windows environment.

A Smooth Transition

Douglas Manness, IT manager at Enns Bros, says, “The transition to IntelliDealer was smooth and without disruption to the business. Technicians and supervisors all moved at the same time, while other users choose their own timing.”

“User training has become easier. We basically provide new staff with a login and they can go through the functionality in IntelliDealer intuitively. Except for a few die-hard green-screen users, everyone finds the new system more productive and easier to use.”

“We can configure the system without changing any code to have our own jargon and terminology displayed as field labels on screens, simply by setting parameters and using the ‘multi-lingual’ facility.”

“We can also create our own custom fields and forms. I cannot comment on LANSA as a development language, but I have noticed that PFW can deliver updates and changes very quickly.”

“From an IT point of view, I find the system very easy to manage. The centralized browser environment allows for quick deployment of changes. I can define many different groups with different levels of security and assign each user with a unique combination of views and authorities needed. The system is robust and available 24*7*365,” says Manness.

The transition to IntelliDealer was smooth and without disruption to the business. User training has become easier. Except for a few die-hard green-screen users, everyone finds the new system more

productive and easier to use.

The Benefits of Real-time Data

IntelliDealer’s Product Support application offers extensive facilities for resource planning and up-to-the-minute monitoring of labor and service-bay utilization. Other modules include CRM, Marketing, Accounts Receivable, Accounts Payable, General Ledger and Payroll. Technicians have access via the IntelliTech module, while customers can access the information via the eServices portal.

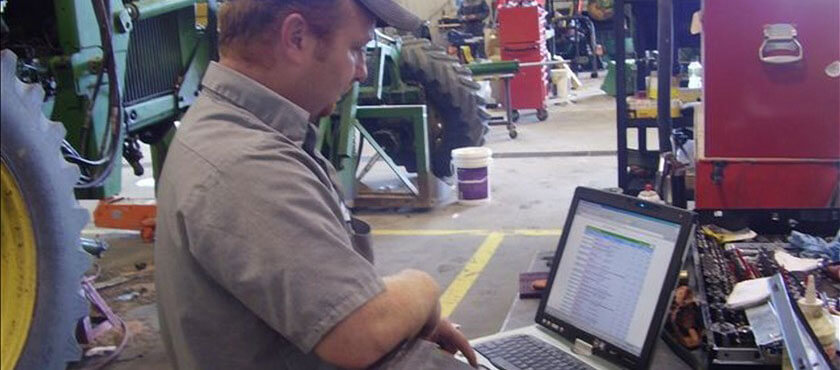

Enns Bros’ 40 technicians, including those in the field, can access IntelliDealer from their wireless laptops, which also have John Deere and Bombardier diagnostic software.

“Technicians don’t have to ask their supervisor what to do next,” says Gregoire. “They can now see on their own laptop which work orders are waiting for them, what exactly needs to be done and how much time is budgeted for the job. They can drill down into the machine’s service history and add their notes. Instead of using a punch card, they use their laptop to record when they start and stop working on a job.”

“Because the information is entered in real time at the source, supervisors have an accurate up-to-the-minute overview of what is going on. They can see which technicians are on duty, which work orders are going over budget, which bays are overbooked and take immediate action.”

“They can also drill into historical data, for example, if a technician frequently exceeds the budgeted time, additional training may be required. Supervisors and managers can make quicker and better decisions.”

“Our eServices customer portal goes far beyond the standard shopping cart site. Customers can access the service history of their machines, view the parts that have been replaced, drill down into past work orders, ask for a quote, schedule a service, reprint invoices and of course they can order parts.”

“Because there is a seasonal aspect in our agricultural business, we get very busy early summer. Customer calls are constantly being put on hold and we often have to call them back. You are at risk of losing sales when you cannot take care of your customers. Customers can now get quicker answers by going on the web.”

“This is a very competitive market. I can go online shopping in my pyjamas on many sites. But with eServices and its complete history of parts used, maintenance and repairs, we offer a superior solution. Even our ATV and Ski-Doo customers don’t feel a need to shop for parts on eBay or anywhere else – because we do it better.”

“Our biggest problem is making our customers aware of the many online tools they can access online. Farmers are quite conservative, while the pick up by the recreational sector is quicker. We hold regular demonstrations and our customers are astonished at how awesome the eServices portal is. The vast majority of customers who have seen eServices demonstrated sign up to use it.”

“Our parts and service business is 10 million dollars annually. eServices can answer the majority of queries related to that business, so even though the uptake by the farmers was initially slow, the eServices portal paid for itself very quickly in reduced phone handling and increased sales.”

Because the information is entered in real-time at the source, supervisors have an accurate up-to-the-minute overview of what is going on and take immediate action.

Total Visibility of Information

“With IntelliDealer, I have total visibility of anything that is going on in the business, right from my computer screen, without interrupting anybody or leaving my desk. To have the right accountability, you need to have the right numbers and I have all the information I need literally at my fingertips,” says Gregoire.

“The system eliminates many wasted man-hours. Before, we were busy being busy. Now, we run a very efficient operation and get done what we want to have done. Our service is improving every day because we have the tools to give better products and better service to our customers,” summarizes Gregoire.

“Having chosen LANSA to make a gradual transition from a green-screen to a browser interface, I can say it really worked well,” says DeDecker.

“Our classic customers didn’t have the risk and interruption associated with a total ERP overhaul and we didn’t have to start from scratch. A lot of our competitors who did start from scratch are still struggling to get the new product out there,” observes DeDecker.

Our parts and service business is 10 million dollars annually, so even though the uptake by the farmers was initially slow, the eServices portal paid for itself very quickly in reduced phone handling and increased sales.

Company and System Information

- Enns Brothers Ltd, headquartered in Oak Bluff Manitoba, Canada, has been serving farmers for over 50 years. It offers John Deere new and used agricultural and lawn & garden equipment and Bombardier ATVs, Ski-Doo’s and other recreational equipment. Equipment sales, parts and services are handled from stores across Manitoba, with over $60 million in annual sales.

- For more information, please visit: www.ennsbros.com

- CDK Global Heavy Equipment, head quartered in London, Ontario, Canada, is a leading provider of management software for Equipment Dealerships throughout North America. CDK IntelliDealer is used by over 1500 dealerships, both as a SaaS solution and on-premise. CDK also works closely together with leading distributors of agriculture and construction related equipment including AGCO, Bobcat, Caterpillar, Ditch Witch, JCB, John Deere, Kobelco, Komatsu, Kubota, Link-Belt, New Holland, Vermeer and Volvo.

- For more information visit http://cdkglobalheavyequipment.com