PLANTION MANAGES MEGA OPERATION WITH SMALL IT TEAM

Plantion, based in Ede in the Netherlands, is one of the most modern and environmentally friendly flower auction and horticulture trade centers in the world. Plantion offers a wide assortment of flowers and ornamental plants at its daily auction and via intermediary services. Plantion uses a LANSA-based in-house developed system to manage grower information, incoming produce, integration with the auction system, compensation to growers, plus the invoicing and distribution to customers.

Ron Nieboer, Application Development Manager at Plantion, says, “Our development workbench has progressed naturally with LANSA. We initially used it for IBM i development, but it has expanded to include Windows applications, PDAs and touch screens. LANSA’s single skill set concept and productivity, combined with the robustness of the IBM i, allow us to manage a complex and time critical mega operation with a very small team.”

Our development workbench has progressed naturally with LANSA.

- The Challenge

- The Auction Solution

- Negotiated Trade System

- The Benefits

- Conclusion/Future

- Company and System Information

The Challenge

Plantion, a co-operative owned by growers, is the result of the 2008 merger between Bloemen Veiling Oost Nederland (Flower Auction East Netherland) and Veiling Vleuten (Auction Vleuten). But it wasn’t until March 2010, when Plantion opened its new €72 million building in Ede, that the two organizations fully merged from an operational point of view. Plantion’s new 60,300 m² location includes a 9,390 m² receiving area, an auction hall with three projected clocks and 400 buyer desks, and a 10,800 m² logistics centre with 21 loading docks. Because of smart building design and energy management, Plantion is enjoying 64 percent less CO2 emissions than the two former sites added together.

Plantion’s growers deliver €250,000 worth of products on a daily basis. These get auctioned in a 2.5 hour time span every weekday morning, starting at 6:00am. During the auction Plantion’s IT systems need to process 4,000 sales transactions per hour, amounting to an average of 10,000 transactions over the course of the auction. In addition, Plantion acts as an intermediary for negotiated trade between growers and buyers.

All the financial and distribution logistics are handled by a LANSA-based in-house developed system called LVS.

Peter Bakker, Director Operations at Plantion, explains, “Our first and foremost priority is system reliability and availability. The auction system, from Aucxis in Belgium, and the LANSA-based distribution system exchange transactions in real-time. If either of these systems were down, slow or inaccurate – especially during the auction – it would stop several hundred buyers and over 100 staff from doing their work. Customers would lose their trust in us and may decide to move to a neighbouring auction for their purchases.”

Another challenging factor, according to Bakker, is the price pressure in the very competitive horticulture industry. “There is no room for inefficiencies anywhere in our company or in the delivery chain. It means that all our divisions, including ICT, need to be proficient and cost effective.”

Before the merger one of the two auction companies was already using the LVS solution. “After careful consideration, the LVS solution was the preferred option for the merged operation,” says Nieboer. “The main reasons to move forward with the LANSA and IBM i based LVS solution were its proven stability and low cost of ownership. Another factor was the flexibility of the LVS system and its easy customization.”

There is no room for inefficiencies anywhere in our company or in the delivery chain.

The Auction Solution

The vastness and sophistication of Plantion’s in-house developed LVS system is best illustrated by looking at the processes it manages, starting from the delivery of goods by the grower to the processing of customer payments.

In the afternoon or evening before the auction, growers send EDI transactions to provide an overview of the produce they plan to deliver. This transaction type is called an EAB, a kind of advance shipment notification specific to the flower industry. The EABs are processed by LVS and then communicated in near real time (every 15 seconds) to the Windows-based Aucxis auction system.

Prospective buyers have internet access to the auction system, allowing them to preview what is going to be auctioned. Customers and growers may also subscribe to a fax or email update about what quantity, type and quality of produce can be expected at the next morning’s auction.

When the flowers arrive at Plantion, inspectors use PDAs that run a Visual LANSA-based application (via telnet) to confirm the delivery and to record any quantity or quality differences with the EAB. Differences are immediately communicated to the Auction system through LVS.

At the auction the clock starts at a high price and rapidly swings down. The first buyer to push the button gets the goods. Buyers in the auction hall have a keyboard on their desk, while remote internet buyers can bid via the Aucxis KOA module, which very smartly manages that the internet and local bids are sequenced correctly. Each auction transaction is transmitted in real-time to the LVS, for further processing.

The flowers arrive and go in front of the auction clock on what is called a CC container, (a.k.a. Danish trolley), a standard trolley in the European flower and pot plant industry. When a buyer purchases a batch of flowers, they usually come together with the trolley. The trolley is scanned and the rental cost for the trolley is transferred from the grower to the buyer. For this purpose LVS sends a transaction to Avalanche, a Windows-based application that keeps track of the CC container balance of growers and buyers.

For those buyer organizations that are subscribed to the service, the LVS will send a real-time EDI message to the buyer’s office with details of the auction transaction. This allows the person who is bidding for the buyer to continue to focus on the clock for his next purchase, instead of having to use his mobile phone to inform his office. Growers get similar EDI updates during the auction, informing them immediately about the proceeds of each auctioned batch.

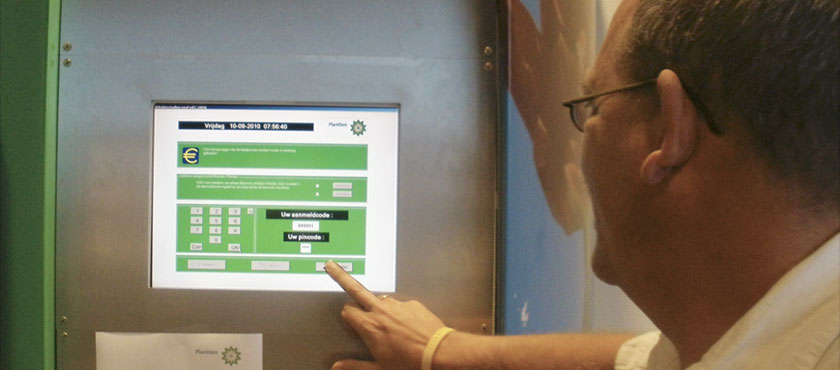

At any time during or after the auction, buyers can walk to one of the many touch screens in and around the auction hall to print their loading-list. The touch screen application, developed with Visual LANSA, is multilingual and allows for left and right handed operation.

After the auction LVS sends EDI invoices to the buyers. All customers have an agreement with Plantion that their account will be automatically debited on the auction day. LVS transmits these debit transactions to Plantion’s bank for collection and can expect same or next day payment.

The system’s functionality is vast and sophisticated.

Negotiated Trade System

Plantion’s turnover in the negotiated trade is nearly equal in value to the auction turnover, but the nature of the transactions is very different. Plantion’s mediation service is often requested for the larger deals, where a buyer or grower doesn’t want to be dependent on the unpredictability of the auction clock.

Plantion’s mediation solution is developed with Visual LANSA and deployed in client/server mode with rich-clients and a DB2/400 database. Even though the application runs on Windows, there are a large number of remote server calls to existing functionality on the IBM i. The Windows and IBM i applications also share business rules and other components through LANSA’s Repository.

The Windows and IBM i applications share rules and other components through LANSA’s Repository.

The Benefits

Plantion’s in-house ICT team is a team of three, consisting of Nieboer plus two people who look after the infrastructure. Nieboer manages application development and integration, with the help of a systems integrator (Ilionix) in project peak times. Nieboer says that this amazing level of productivity in development and maintenance is largely due to good application design and to LANSA. “The speed with which we can develop and maintain in LANSA is absolutely amazing and a major contributing factor to the low cost of ownership of our systems,” he says.

Nieboer feels that his development workbench has expanded and progressed naturally with LANSA. Plantion started with LANSA for iSeries in the mid eighties for native IBM i development and deployment. The company then moved on to Visual LANSA for productive Windows-based development, but initially still with IBM i deployment. Next, using the same Visual LANSA workbench, Plantion started to deploy its applications to the Windows platform. Nieboer is also interested in trying LANSA’s Web Application Modules (WAMs) for rich internet applications (RIA), but hasn’t had the time or urgency yet to experiment with it.

All new development is graphical client/server, but some of the older applications are still in 5250 style. Nieboer may reface these programs or gradually modernize/redevelop them, but says this has a very low priority. “The older applications perform well and there is no problem mixing and matching deployment platforms”, explains Nieboer, “as we can develop, maintain and integrate them from the same workbench.”

Nieboer has always been a big fan of LANSA’s Repository architecture, he says, because it allows applications to share and reuse components, such triggers, program logic, business rules and more. “However, it is crucial to have a set of standards and be disciplined in the way the Repository is used,” he warns. “In LVS’s 20 year history a fleeting number of contractors and developers have worked on the application, so components have not always been consistently defined.”

Plantion has over 20,000 objects in the LANSA Repository (fields, files, triggers, validations, and so on). Nieboer now insists on a strict set of standards and if he happens to change a piece of old code that doesn’t comply, he will put in the effort to make it right, providing time permits. This effort has no doubt contributed to the quality and longevity of LVS.

The speed with which we can develop and maintain in LANSA is absolutely amazing.

Conclusion/Future

“EDI and other direct communication with third parties is getting more important,” says Nieboer about Plantion’s ICT future. “And interfacing with internal applications and packages is becoming imperative as well. I am investigating available business process integration tools, but it is reassuring to know that LANSA is offering a very practical Business Process Integration solution with their Composer product,” says Nieboer.

“Another upcoming development is to release more information to the outside world by providing customers and growers with web access to our systems. Customers can already preview deliveries and buy online via the Aucxis KOA module, but we want to provide access to account, distribution and statistical information as well. For that we can stay within the same Visual LANSA workbench.”

Nieboer expects that more functionality may move to Windows in the future, but that the database will remain on the IBM i, because of the platform’s stability. The platform’s scalability is also important. “Whether we have three clocks or thirty clocks, it doesn’t make a difference to the application’s architecture. LVS will be able to handle it, although I might have to buy a bigger box,” he explains.

But the need for a bigger box isn’t something Plantion will need to worry about soon. During the average auction LVS processes about 4,000 transactions per hour, with a CPU usage of only 16 percent. “Considering we process all auction transactions in real-time, including invoicing, EDI notifications, banking and updating of the sales statistics, there is still room to grow,” concludes Nieboer.

Bakker concludes, “The company merge has provided us with better economies of scale, but even so, we continuously strive to improve our price-performance ratio even further. Our efficient setup with a small and competent in-house team, assisted by a large system integrator for project peak times and second line support, provides a lean yet robust ICT environment.”

Our efficient setup provides a lean yet robust ICT environment.

Company and System Information

- Plantion, a cooperative owned by growers, is the result of the 2008 merger between Bloemen Veiling Oost Nederland (Flower Auction East Netherland) and Veiling Vleuten (Auction Vleuten). Plantion is a one-stop-shop knowledge and trade center for flowers and ornamental plants, with a personal and service centered approach to growers and customers.

- Plantion’s annual turnover exceeds €100 million (2010)

- Plantion deploys two IBM i systems, one for production & development and one for high availability, both IBM i5 model 520.

- The LANSA based LVS system integrates with the Aucxis auction system (www.aucxis.com) and with the Avalanche CC-Container system (www.today-it.nl ), both Windows and SQL server-based.

- For more information visit https://plantion.nl/