LANSA BOOSTS RETURNS FOR DUTCH GROWERS

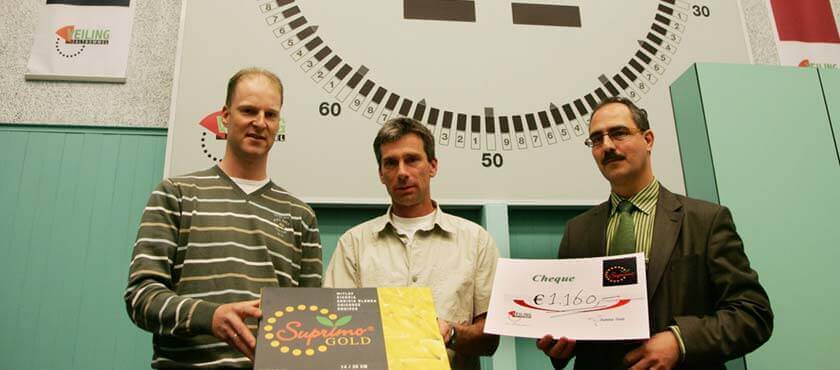

Veiling Zaltbommel, a fruit, vegetable and mushroom auction cooperative in the Netherlands, uses the Internet to make trading between growers and buyers easier and more profitable.

Growers have a wide number of services available to them that can be accessed over the web from their own office or home. One of the services is that growers can enter a prognosis of product deliveries. The prognosis helps Veiling Zaltbommel to timely find additional buyers in case of an expected surplus, and, in case of an expected shortage, to purchase produce from other sources and still meet contractual demands.

Lucien Burnet, IT Manager Veiling Zaltbommel, says “Knowing in advance whether the supply of produce will be over or under the average demand, helps us to get higher revenues for our growers while giving better service to our customers at the same time.”

“The Internet allows our growers to access our system using just a standard browser interface and public Internet connection,” continues Lucien. “This is a very cost effective solution.”

The Internet allows our growers to access our system using just a standard browser interface and public Internet connection, this is a very cost effective solution.

The Challenge

Lucien explains “Fresh produce like the kind that is traded on our auction floor needs to be traded and delivered very fast. Over 95% of what we trade is for the export market. We have contracts with some of our customers to guarantee the delivery of a certain quantity and quality of fruit and vegetables, on a daily basis. You need to have a planning to make that happen. You need to know what will arrive the next day, next week and even next season.”

“We didn’t have a very accurate planning. We had a few people assigned to produce short term planning overviews, based on phone calls and faxes from the growers. This was very time consuming and hectic, because we used to receive a lot of last minute corrections by fax. Our long term planning was mostly based on experience and history and hardly on up-to-date input from our growers.”

“Another short coming in our old system was the entry of the actual delivery details of products. These details needed to be entered on touch-screen terminals that are located in the delivery halls, when the products are delivered. But because most of the growers use trucks and drivers from transport companies, a lot of entry errors were made. This caused confusion and delays.”

“So, both the growers and auction management wanted a to have our growers on-line for more accurate delivery information and a better planning. For years we have put the idea aside, because to develop a privately owned network would not be cost effective. We also did not want to install, maintain and support client software to over 400 growers. When the Internet became so widely accepted, we put the plan back on the agenda.”

The Benefits

“We achieved an enormous labor efficiency in the planning area. We receive daily, weekly and long term planning data directly in our AS/400 database, instead of receiving a large number of faxes. When the pilot project with 15 pepper growers went live, we could free almost one full time staff member’s time. When we will implement the system for our mushroom growers and other fruit and vegetables next season, I expect that we can save another 2 or 3 people in the planning area. On top of that, the data is more accurate as well because we don’t need to retype.”

Leen van Dalen, a pepper grower and one of the first growers to use the system, explains “The new system makes it a lot easier for us. We use trucks and drivers from a transportation company to deliver our products to the auction and often get a different driver. In the old system it was that driver who had to enter the delivery details. This used to create a lot of errors and problems for us. The driver wasn’t very happy either that he had to enter the details. With all the variety in pepper colors, sizes and qualities, you may need to enter more than 12 lines per delivery. Now we can enter the details from home and the auction knows what’s coming well ahead before the actual delivery.”

“Because of improved planning, we now get a better price for our peppers. From March till November we deliver an average of 5,000 kilos peppers each day. But some days we have only 3000 kilos, while on other days we may have 10,000 kilos. If I can inform the auction timely about an over supply, then they can find additional buyers ahead of the auction clock,” enthuses Leen.

Lucien says “To make the Internet solution interesting for our growers, we not only expect them to provide information to us, we also offer extra services to them. It has to work from two sides. We offer general information about quality management, product packaging and other items. Currently we also use LANSA for the Web to develop on-line invoices, price information, price comparisons and daily/weekly/quarterly statistics. Our growers now have access to financial information and can get immediate information on how much their produce sold for that day.

The System

“We considered a PC solution for the Internet. A disadvantage of a PC solution is that we would need to introduce additional hardware and servers. We would also need to worry about the interface between the AS/400 system and the web application on the PC. I have not that much trust in such a PC solution and prefer to keep the entire solution, operations and web access, on the AS/400. We run all our core auction systems on one central e-model AS/400 and find it an extremely reliable machine.”

“The web-based LANSA application allows the growers to enter there product deliveries scheduled for that week and product forecasts for the coming weeks and next season. There is also entry and inquiry of information specific to that grower. ”

“For this project we work together with an IT company in this for the delivery and configuration of PCs and training and support of the growers. Most growers already have a suitable PC, but may still need some assistance with the set-up and configuration. This IT company offers our growers training in Windows and MSOffice as well.”

“We also opened accounts for our growers with a service provider specializing on fast access for companies rather than the low-cost and less demanding private web usage. They offer a very wide bandwidth. Speed is important for the success of the service. Our AS/400 system itself is also connected to the world with a very fast link.”

Conclusion

“Later next year we plan to offer buyers our Internet service as well. We are considering to provide web access to pre-auction deals. This will allow buyers to bid on certain lots outside the auction clock. Now we have our sales staff phoning their relations to offer pre-auction deals.”

“Most of our core systems are developed in LANSA and we find this a very productive development environment. Using LANSA for the Web means that we can use our own staff, who have the business knowledge, to create the web applications in the same productive LANSA tool. LANSA also easily integrates with non LANSA applications, so it was an easy choice,” concludes Lucien.

Company and System Information

- Veiling Zaltbommel is a co-operative owned by a number of growers. Revenue in 1999 was 103 million guilders.

- Products in order of importance are mushrooms, peppers, strawberries, apples, pears and various other fruits and vegetables.

- Growers use Internet service provider UUNet. Veiling Zaltbommel uses world-online to connect its system to the Internet. The PCs used by the growers are configured and installed by Van Loon Automatisering.

- The entire auction administration system is built with LANSA. The auction clock is linked to this system. Quality control staff uses PCs on trolleys and drive around the halls to inspect the products.

- For more information please visit http://veilingzaltbommel.nl

- Both the production systems and web server run on the same AS/400, model 9406, type 620-2175.